Edge MCM Quick Start Solution: Machine Health Made Easier

Arrow and ADLINK — in collaboration with Intel, Microsoft, and SAS — are bringing to market a machine condition monitoring (MCM) that revolutionizes the way manufacturing stakeholders manage machine assets. The Edge MCM is a comprehensive data acquisition and analysis system. It tracks vibration, motion, acoustics, and displacement to capture machine degradation well before humans can notice it.

Reactive vs. Proactive Maintenance

Unplanned CNC machine downtime causes significant disruption to operations, productivity, and the bottom line. Current inspection methods mainly involve maintenance personnel physically checking equipment periodically. This approach is resource-intensive and cannot be scaled easily. Further, complexity and cost of repairs increase after equipment failures occur, compared to preventive measures.

Quick Start Solution Components: Edge MCM with SAS

Power on and immediately visualize sensor data to identify trends and anomalies. No code needed; it comes pre-configured by ADLINK, SAS, and Arrow. Analyze data for insights that lead to optimized maintenance plans and maximum (or longer) machine uptime. Solution components include the ADLINK MCM-100 hardware and the ADLINK Edge IoT middleware platform for edge analytics.

Benefits of the Edge MCM Quick Start Solution

For end-users:

- Reduce downtime and opportunity costs

- Drive new efficiencies

- Gain predictive insights

- Scale from simple monitoring to predictive analysis

For system integrators:

- Complete end-to-end solution

- Increase customer satisfaction

- Enable digitization of legacy equipment

- Drive new value-added services

- Easy-deployment and flexible options

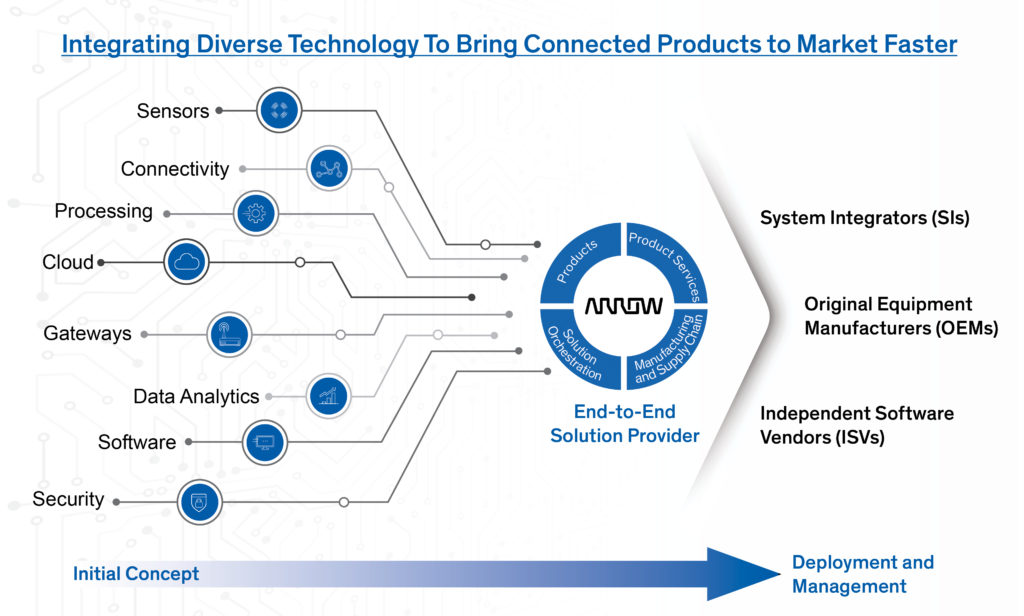

Arrow Intelligent Solutions: Your End-to-End Solution Provider for CNC MCM

Arrow Intelligent Solutions for CNC Machine Condition Monitoring Solution Include:

ADLINK hardware and software customization

Microsoft cloud engineering

SAS data analytics and modeling

Installation and deployments at scale